Anti Moisture Powder

Anti moisture powder is an essential additive in various manufacturing processes, particularly in the production of plastics and rubber. This compound effectively absorbs excess moisture from raw materials, preventing defects and ensuring high-quality end products. By using anti moisture powder, manufacturers can avoid common issues like bubbles, voids, and surface imperfections, leading to more reliable and aesthetically pleasing products.

In the plastics industry, anti moisture powder plays a crucial role in enhancing the properties of materials like polyethylene and polypropylene. During the extrusion and molding processes, moisture can cause significant problems, including reduced strength and durability. Incorporating anti moisture powder into the production process ensures that these materials maintain their integrity and perform optimally in various applications, from packaging to automotive parts.

The benefits of anti moisture powder extend to the rubber industry as well, where it helps in producing superior quality rubber products. Moisture can negatively impact the curing process, resulting in compromised flexibility and resilience. By adding anti moisture powder to rubber compounds, manufacturers can achieve consistent quality and performance, essential for products like tires, seals, and gaskets. Overall, anti moisture powder is a key ingredient that enhances the efficiency and reliability of manufacturing processes across multiple industries.

0M [Zero Moisture]

OM is a specially modified universal product meant for use in virgin or recycling polymers industry. OM absorbs moisture from the system which otherwise cannot be removed through conventional methods. The designed product is readily dispersible virtually in any system and does not clog/ choke filtering mesh/jali. OM is inert and does not affect the final properties of the product mechanically or chemically.

![0M [Zero Moisture]](https://sschemindia.com/wp-content/uploads/2024/05/0M-Zero-Moisture.png)

DESCRIPTION

| Appearance: | Off White, Non Dusting Powder |

| Density at 25⁰ C: | Approx. 3.3 gm/cm3 |

| Discoloration[During Heat]: | None |

| Packing: | 1Kg. Packet /10 /25 Kg in Bags |

| Desiccant Base: | CaO and additives |

| Particle Size d90: | =< 20 µm |

| Storage Stability: | In packed & sealed conditions 6 months maximum |

| Application: | Extrusion/Molding of virgin or recycling of polymeric material or Where Cellulosic fiber like Wood or other fillers containing Moisture are used. |

| Dosage: | 1 to 10 phr.[Depending upon the moisture Content]. |

0M [Zero Moisture]

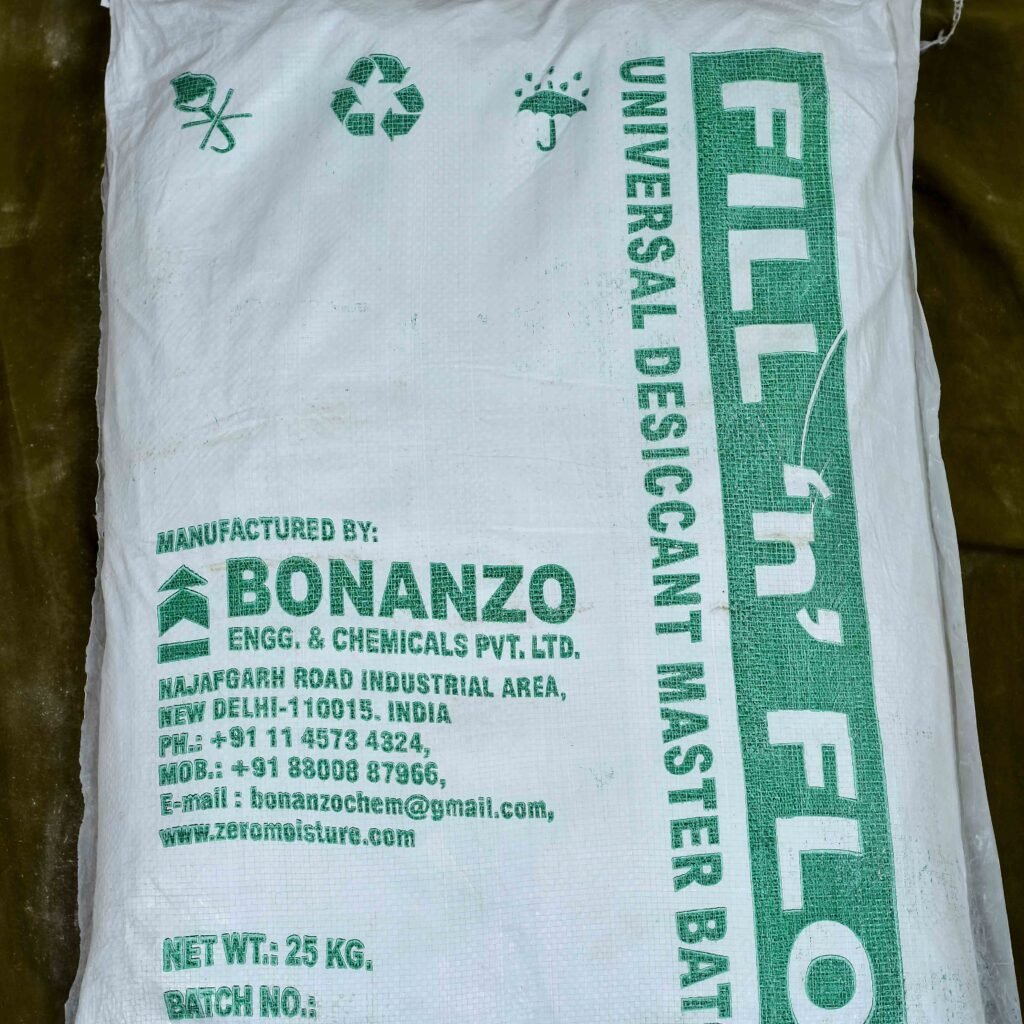

FILL & FLO [Desiccant Masterbatch]

Generally polymers are hygroscopic and they release the moisture during extrusion / processing. The moisture when released spoils the surface of the product by giving blisters, fisheyes and week structure. To overcome this we have developed universal desiccant masterbatch under the brand name ‘FILL & FLO’. Fill &Flo is formulated with high quality fine powder of less than 20µm. Due to special formulation it disperses in the system quickly and homogenously.

Fill & Flo absorb the moisture 20% of the weight of masterbatch itself. Use the ordinary equipment, no need change the processing technology. It is Non-toxic, no stimulation, good plasticizing and Uniform particle size. It is add into the toughening agent , so as improve the toughness.

Fill & Flo reacts with the moisture and eliminates it. This enhances the surface finish, flow of the material thus increases the properties of the end product. It is compatible for LD, PP, EVA and the wetting plastic such as Blow Film, Plastic Piece, Plastic Pipe, Blow Molding, Coating Film and Injecting.

DESCRIPTION

Heat Stability:

| Appearance: | Off White |

| Carrier: | PE |

| Moisture absorbent content: | >80% |

| MFI [230⁰C/10min]: | 5~10g/10min |

| Melting Point: | 130⁰C |

| Volatility: | 1.5+_0.5% |

| Bulk Density: | 1.2+_ 0.1g/m3 |

| 250⁰C | |

| Form: | Pallets |

| Packing [net weight]: | 25 Kg |

Applications

- PVC PIPES/ PROFILES & FITTINGS

- PVC WIRES & CABLES

- COLOUR/FUNTIONAL MASTERBATCHES

- FILLED COMPOUNDS FO MOULDED FURNITURE

- FILLER MASTERBATCHES

- EVA FOOTWEAR